HSLA Column Pipe

Built from high-strength, corrosion-resistant HSLA steel, this column is NSF 61 certified, AIS compliant, and eliminates the need for epoxy coating. Proven through field and lab testing for superior performance.

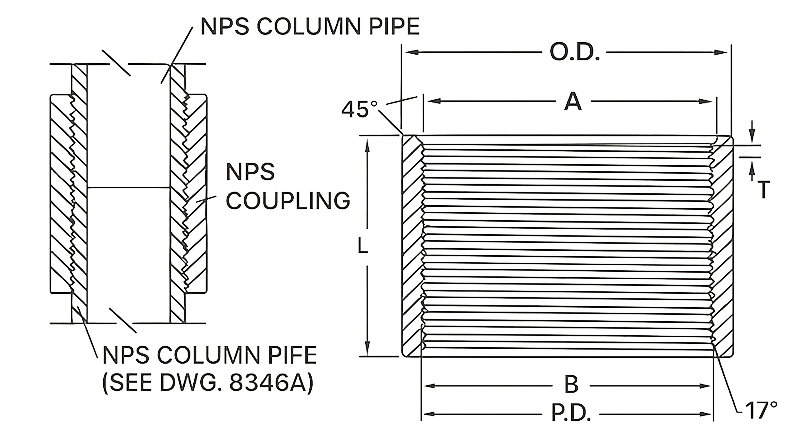

Straight Butt Thread

| Pipe Diameter | Wall Thickness | TPI | A | Minor Diameter B |

|---|---|---|---|---|

| 6.625 | 0.250 0.312 |

8 | 6.700 | 6.454–6.440 |

| 8.625 | 0.312 0.375 |

8 | 8.700 | 8.454–8.440 |

| 10.750 | 0.312 0.375 |

8 | 10.812 | 10.580–10.566 |

| 12.750 | 0.375 | 8 | 12.812 | 12.554–12.542 |

| Coupling OD | L | P.D. | T |

|---|---|---|---|

| 7.312 | 4.125 | 6.527–6.517 | 0.250 |

| 9.625 | 4.624 | 8.529–8.517 | 0.250 |

| 11.750 | 6.125 | 10.652–10.642 | 0.250 |

| 13.937 | 6.125 | 12.652–12.642 | 0.250 |

Values listed in inches. Additional Wall Thicknesses available.

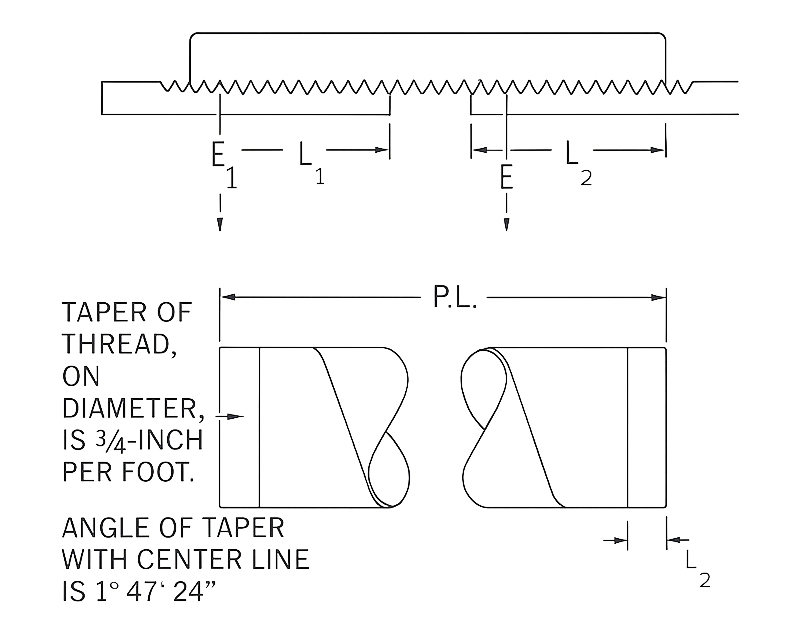

Tapered Thread (NPT)

0.9586.505

| Pipe Diameter | Wall Thickness | Length L₁ | Diameter E₁ |

|---|---|---|---|

| 6.625 | 0.250 0.312 |

||

| 8.625 | 0.312 0.375 |

1.063 | 8.500 |

| 10.750 | 0.312 0.375 |

1.210 | 10.620 |

| 12.750 | 0.375 | 1.360 | 12.617 |

| Effective Thread Diameter E₂ | Wrench Make Up | Thread Overall Length L₂ |

|---|---|---|

| 6.540 | 1.188 | 1.946 |

| 8.540 | 1.312 | 2.146 |

| 10.665 | 1.500 | 2.358 |

| 12.665 | 1.630 | 2.558 |

The Evolution of Pipe: Not Your Grandfather’s Pipe

Typical % Composition By Weight

Strength in PSI

| Time Period | Steel Type | CU | CR | NI | SI | P | G101 Corrosion Index | Yield | Tensile |

|---|---|---|---|---|---|---|---|---|---|

| 1900 – 1940 | Hard Red | 0.20 | 0.00 | 0.00 | 0.00 | 0.01 | 4.11 | 55,000 | 70,000 |

| 1940 – 1980 | COR-TEN | 0.41 | 0.84 | 0.28 | 0.48 | 0.09 | 8.35 | 50,000 | 70,000 |

| 1940 – 1980 | Kai-Well | 0.27 | 0.00 | 0.09 | 0.09 | 0.04 | 5.36 | 55,000 | 70,000 |

| 1940 – 1980 | USS Well Casing | 0.26 | 0.00 | 0.00 | 0.08 | 0.03 | 5.06 | 50,000 | 70,000 |

| 1980 – Present | HSLA ASTM A606 Type 4 | 0.31 | 0.72 | 0.26 | 0.29 | 0.02 | 6.87 | 55,000 | 75,000 |

| 1980 – Present | Copper Bearing | 0.20 | 0.02 | 0.01 | 0.00 | 0.03 | 3.91 | 44,000 | 68,000 |

| 1980 – Present | Mild Steel | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 35,000 | 50,000 |

Understanding the Protective Coating of ASTM A606 Type 4 Steel

ASTM A606 Type 4, also known as weathering steel or COR-TEN®, is a high-strength, low-alloy (HSLA) steel that develops a natural, protective rust layer over time. This self-sealing oxide layer eliminates the need for painting or other corrosion prevention methods, making it ideal for exposed structural and architectural applications.

We’ve published a technical memo detailing the electrochemical process behind the formation of this protective coating, including the role of alloying elements like copper, chromium, and phosphorus.